SUSTAINABILITY REPORT 2023/24

Read about how we are strengthening our sustainability efforts step by step

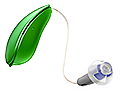

Any colour you

CAN

POSSIBLY

IMAGINE

CLEANROOM PRODUCTION

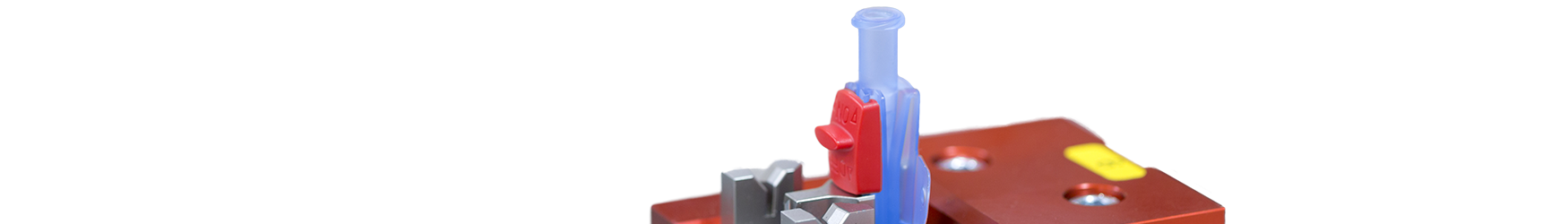

Injection moulding and assembly of disposables

ISO 13485:2016 Class 8

Since the 1950s, we have been working with injection moulding of plastic. With extensive experience in refining different types of plastics, we have placed ourselves among the foremost in our niche. Today, we specialize in injection moulding and surface treatment of plastics, primarily in the medical technology field.

We can offer a long refining chain from construction and tool development to injection molding, surface treatment and assembly in high-volume manufacturing. We also have a clean room class 8 with fully automatic assembly of disposable medical items.

We contribute our value-creating expertise from initial sketch to finished product. Our basic services consist of project management and product development/design support for plastic components. Our processes include toolmaking, injection moulding and assembly (also cleanroom), and advanced functional and decorative surface treatment. We can perform all of your processes under one roof, for both short and long production runs. Plastic parts. Refined.

Medical device solutions, both equipment and disposables. Injection moulding and advanced assembly in class 8 cleanrooms and surface treatment of plastic parts for various purposes.

Refined plastic components included in electronic applications. Injection moulding, EMC shielding and other surface treatments, EPA assembly, final inspection.

Parts with high standards regarding mechanical properties, precision and durability, and where the application is more often than not in an exposed environment. Injection moulding, surface treatment, marking and assembly.

Parts where the principal issue is form and appearance, often in combination with different surface treatment solutions. Injection moulding, metallising, lacquering and assembly.

AMB is in the final stages of a major investment period, including a 5,500 sqm expansion and a solar park expected to produce 2 GWh per year.

© 2025 — AMB Industri AB